Total

AFM 1665 Dryden AQUA mechanical filtration up to 5 microns and deferrization

1059.00 €

Compare products

AFM - a high-tech filtering material, the raw material for the manufacture of which is green glass packaging.

Three factors play an important role for the filter media:

Three factors play an important role for the filter media:

- Mechanical filtration;

- Adsorption reactions;

- Coagulation and flocculation efficiency.

It is known that sand and non-activated crushed glass become a biofilter for several months. Bacteria adversely affect the mechanical filtration performance and promote the formation of channels in the filter media. In the case of AFM, phenomena such as the formation of lumps and channels do not occur.

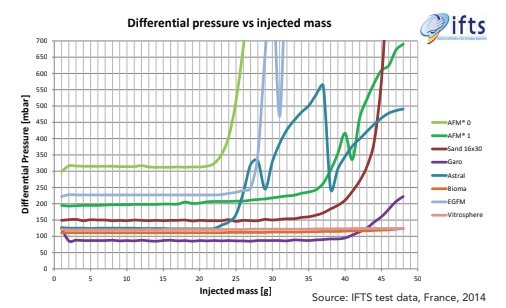

AFM removes 80% of all particles in water up to 4.5 microns in size. The best cleaning result, which can give high-quality sand - 8 microns.

The results were obtained on filters operating at a filtration rate of 20 m / h without flocculation. Therefore, the results give a direct comparison of various filter materials.

The chemistry of glass, the shape of the particles, and especially the activation process give AFM important properties, clearly superior to sand and glass sand as filter fillers. The large surface of the particles has a strong negative charge for adsorption of organic substances and small particles.

The surface also has catalysts in the form of metal oxides, which produce free radicals and, thus, a high redox potential (redox). Therefore, AFM is self-disinfecting. AFM prevents the formation of bacteria colonies and is a unique, bio-resistant filter material.

The ability to hold particles is a very important moment in any filtration system. In drinking water and in swimming pool systems, where crypto-sporidia represent a high risk of disease, filters must be stable and capable of holding parasites. Sand and AFM were the only materials that created a sustainable filtration barrier.

AFM activation is a patent protected 3-step process during which the structure of the glass surface changes at the molecular level. Glass is an aluminosilicate; in the process of activation, the already existing properties of green glass are used, therefore, Dryden Acqua uses only green glass containers. In addition, the manufacturing process enhances the properties of glass by:

- Enhance its catalytic properties;

- Control of charge density on its surface;

- Increasing the area of its surface;

- Control of selective molecular surface structure.

Techical specifications:

- Column - 1665;

- Throat diameter - 2.5 ";

- Volume l. - 186.56;

- Empty weight - 14.8 kg;

- Maximum pressure - 10 bar;

- The maximum water temperature is 49 ° C.